Concrete Overlays

Key Design Considerations

Overlays | Installation Process | Design Factors | Success Story | Ultra-Thin Overlays

Preparing proper construction specifications for concrete parking lots has recently been made much simpler with the publication of ACI's Standard Specification for Plain Concrete Parking Lots (ACI 330.1). This standard covers the minimum requirements for the construction of plain (unreinforced) concrete parking lots on grade, including materials, placing, texturing, curing, jointing, and opening to traffic. These specifications can be included as part of the project documents by reference or by incorporating them in their entirety.

A copy of ACT 330.1 is available from the American Concrete Institute, P.0. Box 19150, Detroit, MI 48219 (Phone: 313-532-2600)

Evaluating an Existing Parking Lot

To ensure satisfactory performance of a new concrete overlay, the factors that caused deterioration of the existing asphalt parking lot need to be corrected and recognized in the design. The engineer should examine the existing pavement to find the probable reasons for its deterioration. Asphalt pavement failures are generally due to one or more of these factors:

Heavy traffic

Drainage problems

Poor construction

Inadequate subgrade conditions

Substandard conditions

Overlay Thickness Design

Once existing site conditions have been analyzed and the factors that contributed to pavement failure have been determined, the design of the parking lot overlay can begin. First, the thickness of the new concrete surface must be determined by considering the type and volume of traffic expected, the strength of the existing pavement, and the material properties of the concrete to be used.

Once existing site conditions have been analyzed and the factors that contributed to pavement failure have been determined, the design of the parking lot overlay can begin. First, the thickness of the new concrete surface must be determined by considering the type and volume of traffic expected, the strength of the existing pavement, and the material properties of the concrete to be used.

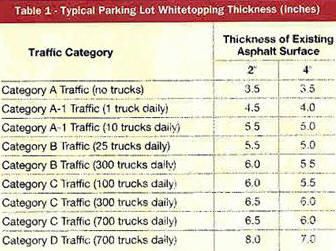

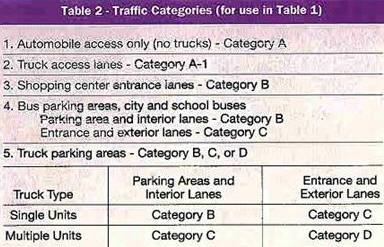

The American Concrete Institute Guide for the Design and Construction of Concrete Parking Lots (ACI Committee 330) provides direction on thickness selection for both new construction and overlays. Table 1 above summarizes overlay/whitetopping thickness design for typical values of traffic, concrete strength, and subgrade support. Traffic categories are described in Table 2.

Table 1 assumes a concrete flexural strength of 600 psi (approximately a 4000-psi compressive strength) and a modulus of subgrade reaction (k) of 100 pounds per cubic inch for the base material below the existing asphalt layer. For different traffic conditions, concrete strengths, and subgrade support, consult ACI 330.

Special Considerations for Badly Failed Areas

Areas of the existing asphalt parking lot that show excessive deterioration should be singled out for special treatment. If the failure is caused by heavy truck traffic, which is common around trash and pickup containers, the overlay in those areas should be specifically designed for the heavier traffic.

Areas of the existing asphalt parking lot that show excessive deterioration should be singled out for special treatment. If the failure is caused by heavy truck traffic, which is common around trash and pickup containers, the overlay in those areas should be specifically designed for the heavier traffic.

Concrete can be placed directly on rutted asphalt when the ruts are less than 2 inches deep. Potholes, however, should be filled with a well-compacted aggregate base material. In large areas with severe subgrade failure, the unsuitable material must be excavated and replaced. A thin layer of sand may be needed to prevent intrusion of the subgrade material into the base course. Before placing the overlay, the elevation of the new subgrade material should match the existing pavement grade.

Drainage and Grade Problems

During the design process, the engineer should check the original design to ensure that catch basins and storm drainage structures are adequate to carry away the anticipated stormwater. The overlay should be graded to provide a minimum fall of 1/8-inch per foot toward the drainage structure. The drain inlets and manholes should be raised to match the elevation of the new pavement.

In some cases, it may not be possible to raise the elevations of existing curbs or building entrances. In these situations, the existing pavement abutting the structure should be removed in a tapered section out to the location of the first joint in the concrete over-lay. Underlying materials in the section should be adequately compacted. At vehicle entrances, the thick end of the tapered section should be excavated to allow for an additional 20-25% thickness of the concrete. This increased thickness compensates for the support lost by removing the original pavement material.

Joint Design

The design guidelines given in ACI 330 are generally appropriate for whitetopping. However, concrete placed on existing asphalt experiences much more subgrade restraint than concrete placed on an unstabilized subbase or subgrade.

The design guidelines given in ACI 330 are generally appropriate for whitetopping. However, concrete placed on existing asphalt experiences much more subgrade restraint than concrete placed on an unstabilized subbase or subgrade.

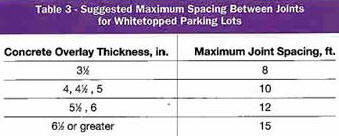

To best control cracking, the maximum spacing between joints should be kept at the lower limits recommended by ACI 330. Table 3 suggests maximum joint spacings for white-topped parking areas. These spacings should be modified based on local experience.

In addition to joint spacing, the following suggestions for joint layout can improve overlay performance:

Joints should be laid out to form approximate square panels. When this is not practical, rectangular panels can be used if the long dimension is no more than 1.25 times the short dimension.

The maximum angle between two intersecting joints should be limited to 80 degrees.

Joints must intersect pavement-free edges at a 90-degree angle and extend straight inward for a minimum of 1.5 feet from the pavement edge.

The joints should be aligned in adjacent panels.

Joints in attached curbs should be aligned with the pavement joints.

Where there are manholes, catch basins, small foundations, and other built-in structures, the joints should be laid out so that they meet the corners of the structure.

Isolation (expansion) joints should be used only to isolate fixed objects abutting or within the pavement area. ACI 330 recommends constructing control joints to a depth of at least one-fourth the pavement thickness in order to control cracking. This is generally adequate for concrete parking areas built on shaped subgrades or subbases, where the final thickness of the slab can be well-controlled. For overlays, however, the concrete overlay is placed on an existing asphalt pavement, which may contain ruts, dips, and other surface distortions.

Though the minimum overlay thickness should be carefully controlled to ensure adequate pavement strength, the concrete overlay may be thicker in some areas than the minimum thickness specified by the designer. In addition, the asphalt base restrains the concrete pavement more than an untreated base material does. Control joints, therefore, should be deeper for overlayed parking lots than for new construction. Control joints should be constructed to a minimum depth of one-third the overlay thickness.